PLC for press brake

PLC

(Programmable Logic Controller)

This is very important unit responsible for the correct operation of the machine, protection against defects and - in our release - for operator safety.

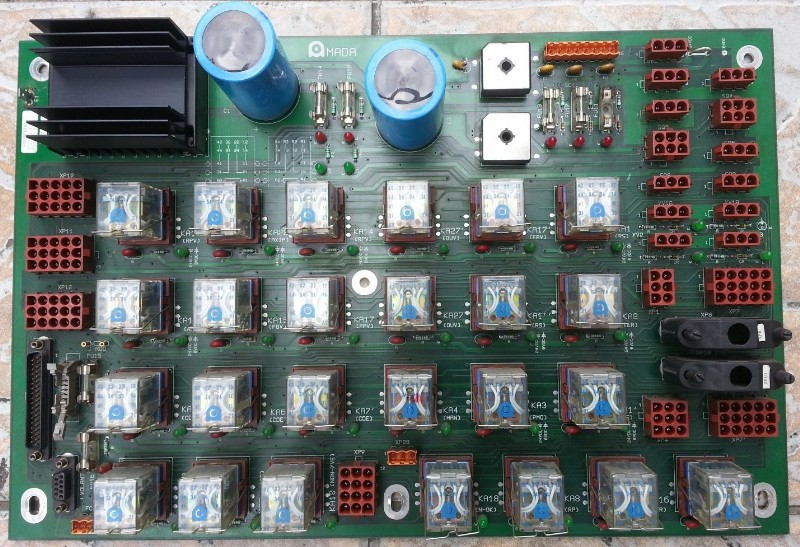

In old machines were implemented PLC made from relays and contactors. The disadvantage of such solution is the high difficulty of any changes to the program "saved" in wires and relays connections and ...

PLC emoved from the press brake AMADA,

here connections anre on a printed circuit board

and change the program is virtually impossible

ß

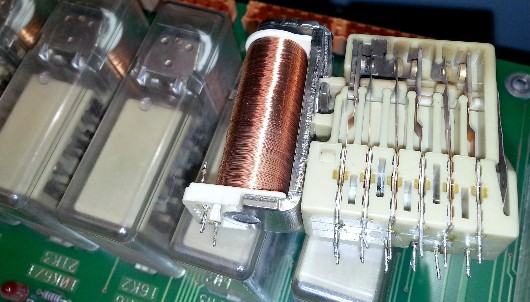

... and time-consuming search for reasons for defects or the absence of permits.

not easy to find such a problem, difficult to desolder it, but find not burnt replacement - it's just a challenge

Ü

(I guess it's from some press Beyeler)

Therefore, a much better, more reliable and practical are digital logic controllers ...

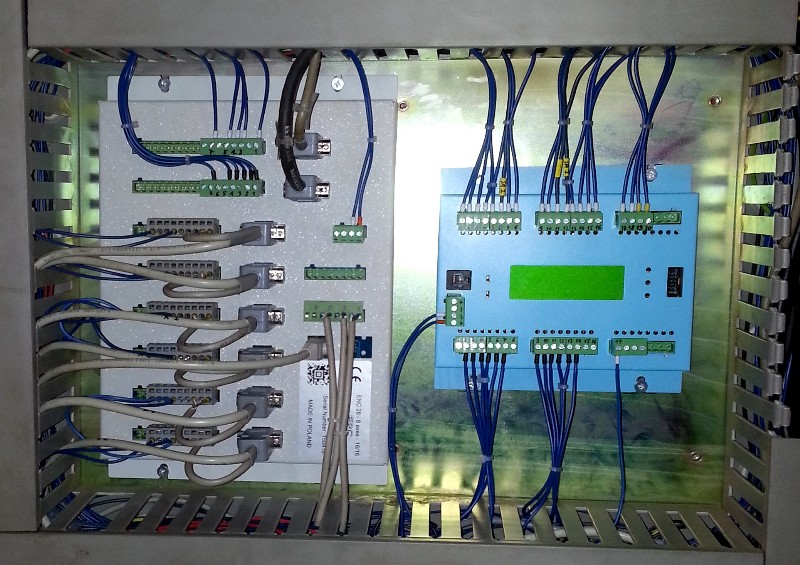

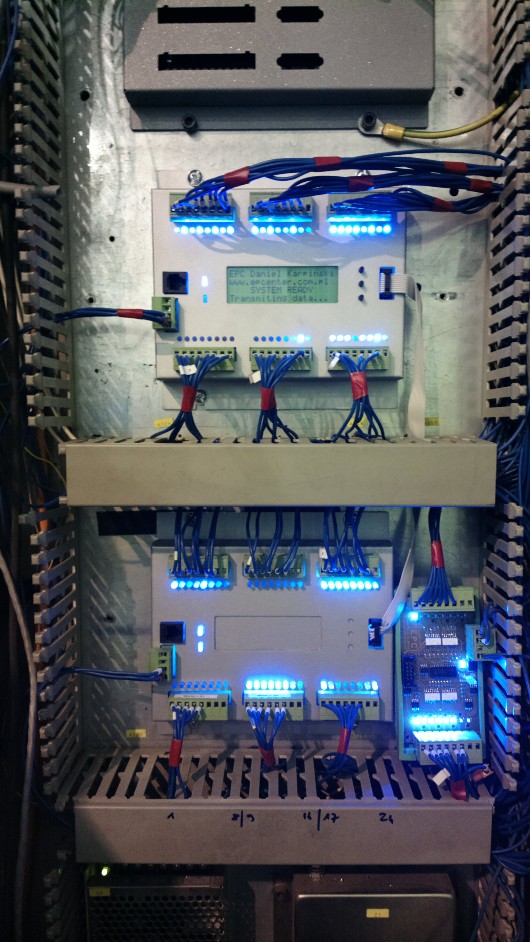

The basic module has 24 inputs and 24 outputs. If you need more I / O, this PLC can be extended by connecting next module.

on the left - ENC of our controll system, on the right - PLC

ß installed in 8-axes press brake ß

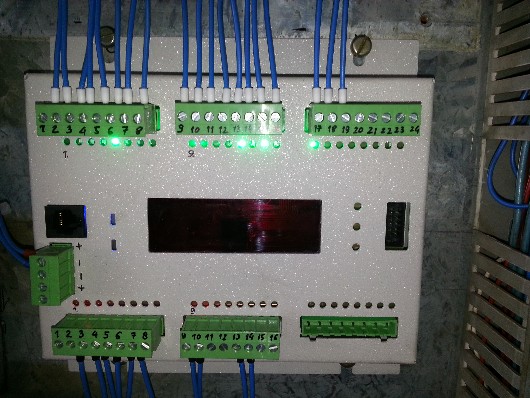

The inputs are used to monitor the state of elements of the machine - limit switches, position sensors of axle components, slant of the beam, doors or covers opening, pressing of buttons by the operator, emergency stop switches, position of the switches - as well as orders from the main control and the operator (pedal, push buttons 2-hands, upward movement).

Outputs run all important elements of the machine - they open and switch the appropriate hydraulic and pneumatic valves, allow to work hydraulic pumps, allow the movement of axis, deliver machine status feedback to the main controller.

Between inputs and outputs there is what is the most important - the logic controller with a program that analyzes the situation at the inputs and in response activates the respective outputs accordingly.

Eg. during the fast move down of the beam PLC opens security valves and fast movement valves then at programmed distance above the plate will switch to slow movement valves.

PLC will not allow the simultaneous execution of two commands, eg. move up and down.

In our PLC can change the program within minutes without having to re-wire of half of the Control switchbox,

and the diagnosis of a failer is easy and "by eye" - just take a look whether the respective I / O lamps are ON.

Ü